Volunteers weatherize Thetford Elementary, Efficiency Vermont takes note

The elementary school is the town's largest public facility and consumes approximately 12,000-13,000 gallons of heating fuel per year.

WindowDressers is a Maine-based nonprofit that builds insulating window inserts, "In 2018, over 1,000 volunteers worked together to build 7,597 inserts at 33 Community Builds across the state [of Maine]. In 2018, 34% of our inserts went for free to low-income households."

Since its inception, WindowDressers insulating window inserts have saved an estimated 880,000 gallons of heating fuel and over $2.2 million at today’s fuel prices.

– WindowDressers website

WindowDressers first appeared in Vermont via the Glover Energy Committee, which presented their efforts in Glover to VECAN (Vermont Energy and Climate Action Network) in 2018. This is where members of the Thetford Energy Committee first learned about the inserts. Energy Committees in Thetford and Strafford partnered in 2019 for their first Community Build, building 146 window inserts for homes in the two towns.

Everything took a pause in 2020 due to the pandemic as volunteers were unable to enter people's homes to measure window openings or to gather indoors to assemble frames. The Thetford Energy Committee kept working in 2020, however, by reorganizing into a joint Town and School Energy Committee and developing plans to install inserts at Thetford Elementary School.

The elementary school is the town's largest public facility and consumes roughly 12,000-13,000 gallons of heating fuel per year.

In 2021, volunteers measured every window in the school as well as in the homes of 77 Thetford and Strafford residences. Those measurements were then sent to WindowDressers in Maine, where the wood frame components were drilled and cut to length. Volunteers brought them to Thetford, and more than 100 volunteers assembled the 308 residential inserts and 125 inserts for the school in the North Thetford Church.

In 2021, funding came from Mascoma Savings Bank, New England Grassroots Environment Fund, Ompompanoosuc Community Trust, and several individuals. These funds were used to help subsidize costs for participating households and the school.

– Bob Walker

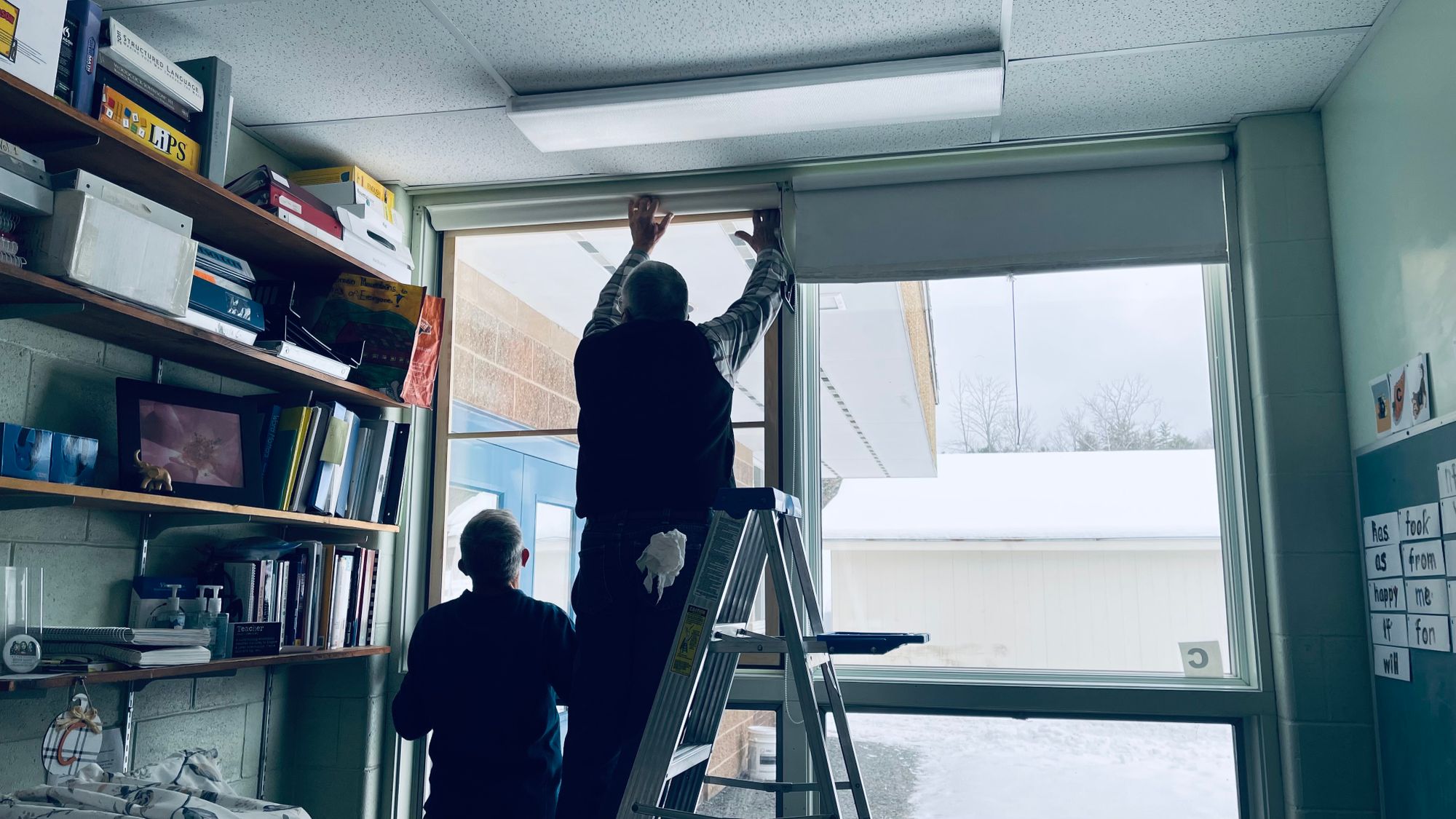

Then came the big day: installation at Thetford Elementary. On Monday, December 27th, volunteers gathered in the cafeteria of the school. Bob Walker, the super-volunteer behind the entire effort, walked everyone through the installation process.

Every insert was labeled with the room number and specific window it was built to fit.

The windows were brought from the cafeteria to their corresponding rooms.

Once the windows were where they needed to be, installation was pretty easy. Foam weatherstripping on the exterior of the wood frame allowed the inserts to fit snugly into place. No tools were required.

WindowDressers are gaining popularity in Vermont. Energy Committees from an estimated 15 municipalities took part in a Community Build this year, including Burlington, Brattleboro, and Montpelier. That's up from about a half dozen in 2019. Homeowners installing at least 3 inserts are eligible for up to $100 in incentives through Efficiency Vermont's (EVT) DIY Weatherization rebate.

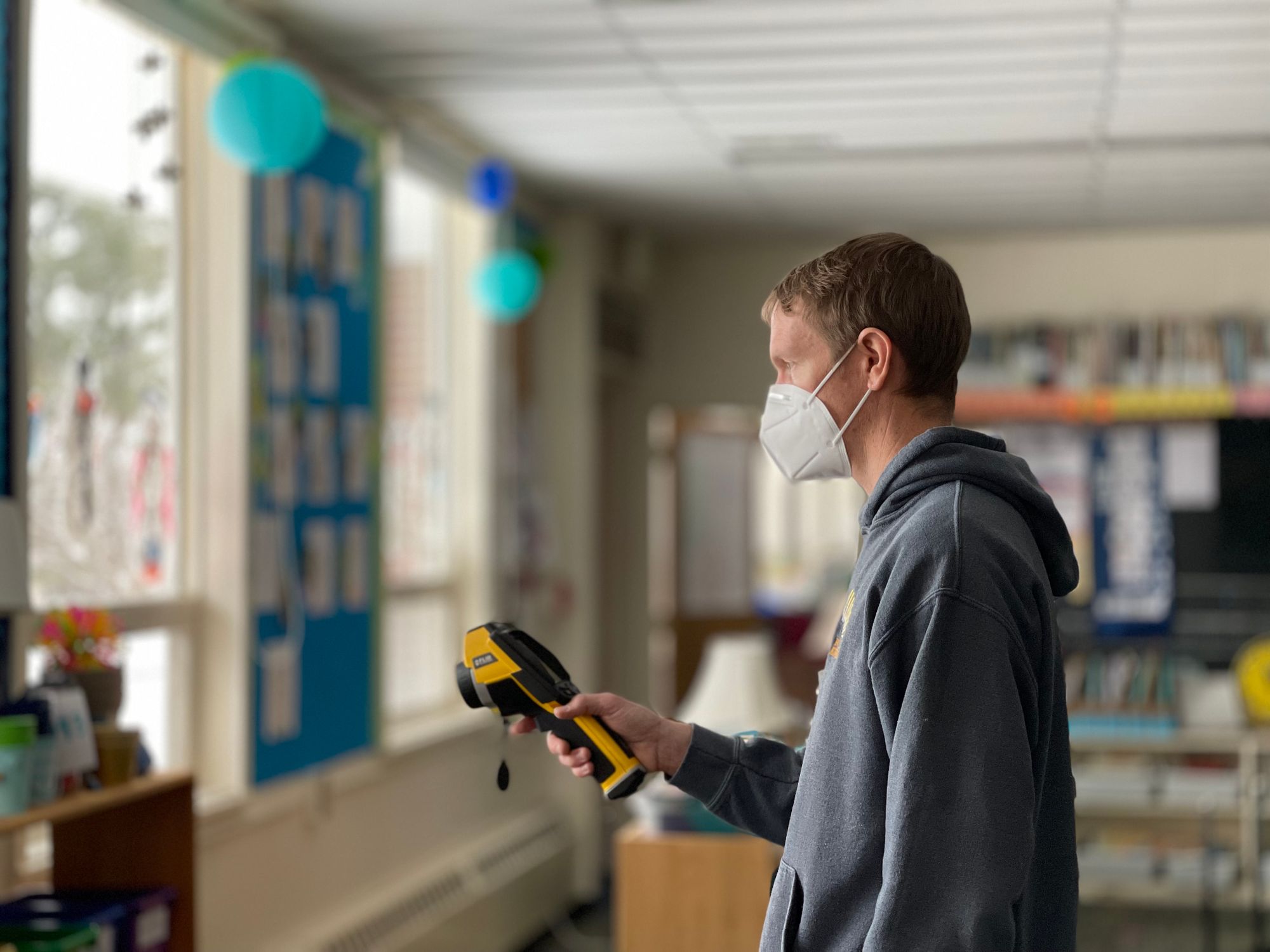

EVT doesn't have a lot of hard data on the inserts' effectiveness. This is what makes the installation at Thetford Elementary all the more interesting: EVT supported two local energy contractors to come and study the effectiveness of the inserts. Three different methods were employed.

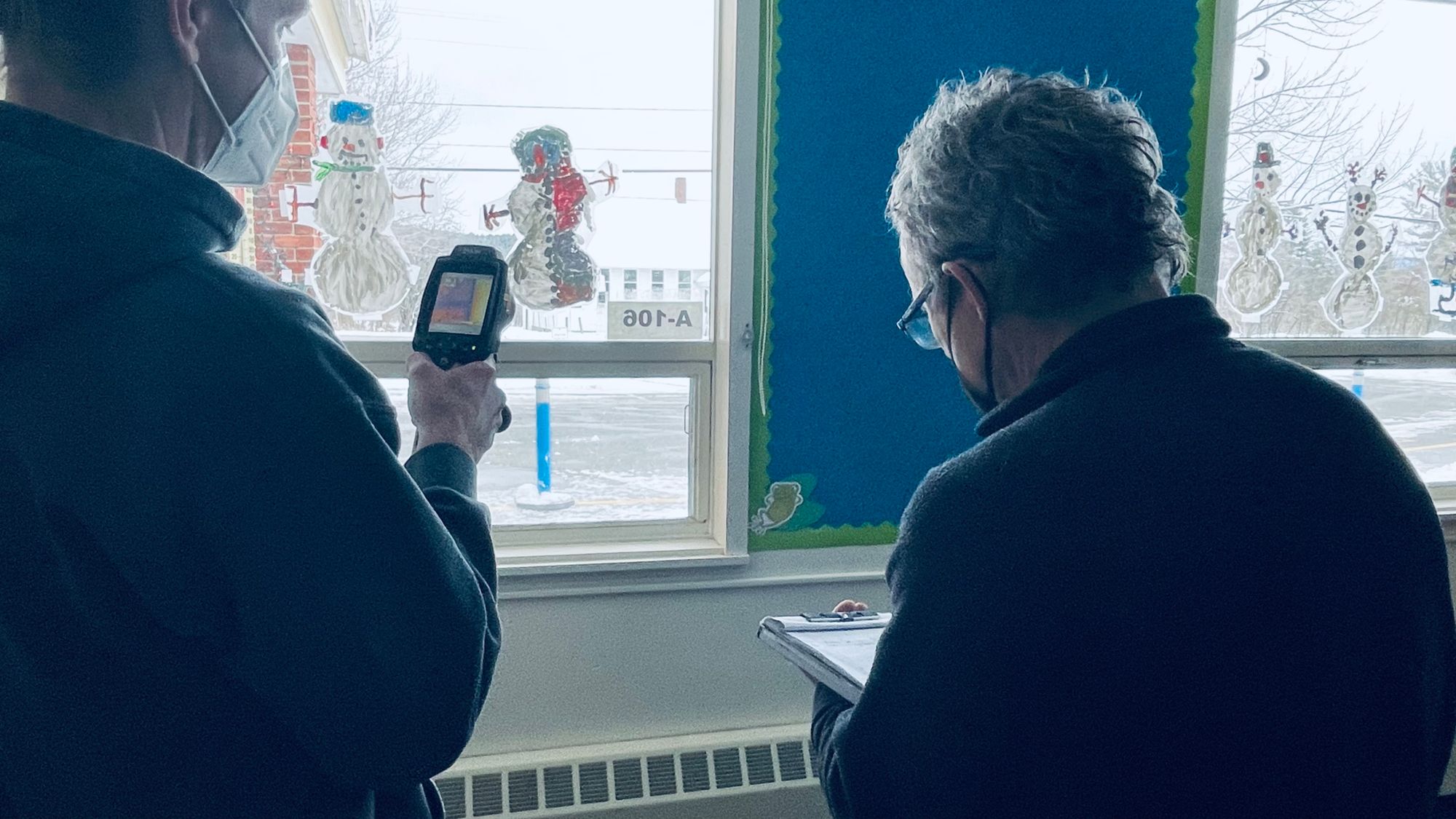

Brent Mellen, a Thetford resident and manager of Building Energy’s office in Wilder, employed two methods—an infrared thermometer and a blower door test, both of which are commonly used for residential and commercial energy audits.

For the infrared test, Brent attempted to determine the temperature on the surface of the window glass. Along with the outdoor and indoor air temperatures, calculations can be made to determine heat loss both before and after the window inserts have been installed.

He also checked the temperature of the frames around the glass. Some materials, such as metal, are more conductive and are therefore responsible for more heat loss. The windows in the original 1961 section of the building were all found to have metal frames.

Jamey Gerlaugh, a representative from EVT, wrote down the results as Brent walked through the building, helping Brent work more efficiently.

There are a lot of variables with this test. For example, the baseboard heaters are right below the windows. Where they are in their on/off cycle could impact readings. Another variable could be radiant heat from Brent himself. Brent had to stand back and to the side to ensure the glass surface wasn't picking up his body heat.

Unfortunately, this test did not prove very effective due to the limitations of infrared. While Brent did detect about a 10-degree difference in the temperatures in the lower wing, which have older, single-pane windows, and the upper wing, which have newer, double-paned windows with (seemingly) low-e coatings, the infrared thermometer struggled with the transparent and reflective surfaces. Infrared is commonly used for measuring wall and ceiling temperatures, not glass and plastic. Readings from after the installation of the inserts appeared to be unchanged even though the inserts were notably warmer to the touch than the glass had been.

The next test was the blower door, which works by de-pressurizing the building and then measuring the resulting amount of air flow.

Six large fans were installed in exterior doors. Due to the size of the building, there were two each in the lower and upper wings and two in the gym for a total of six fans. A typical blower door test for a home usually requires only one fan, and new, energy-efficient construction requires one fan about a third the size as the ones used here and in older homes.

The fans blow air out of the building, creating a set negative pressure. Nature loves to find equilibrium, but air can't fight the high-powered fans. Instead, air sneaks in through gaps in the building's foundation, attic, windows, and around doors. The more gaps there are, the more air can come in and the more air, in turn, the fans have to blow out to maintain the set negative pressure. The amount of air being blown out therefore determines how "leaky" the building is.

Brent performed one test before and one test after the inserts were installed.

However, this test also proved challenging in the case of Thetford Elementary, where most of the windows that received inserts were fixed picture windows. Heat loss through fixed windows usually comes through conductivity (what the infrared was hoping to measure), not air infiltration. It will take Brent some time to crunch the numbers, but he thinks the impact of the inserts on air infiltration will be minimal due to the large number of fixed windows in the building.

"I think these inserts will prove really effective in schools/buildings with a lot of double-hung windows, where air leakage is more of an issue," Brent said. He also thinks they'll be most effective on single-pane windows. The gain from going from single- to double-paned windows is significant. The window inserts essentially act as a second pane, but at a fraction of the cost.

The third test – and perhaps the most promising – was performed by Chris Hebb, Thetford resident and owner of Dynamic Integrations, a Post Mills energy consulting company. Chris has been monitoring fuel consumption directly from the school's boilers for the past several weeks, and will continue to monitor fuel consumption into January, looking for decreases in consumption that could be attributable to the newly-installed inserts. To do this, Chris had to hardwire his own sensors into the school's system.

The sensors, one for each boiler, feed into a laptop which is then backed up in the cloud.

It's not so simple, though. Outside temperatures do not stay constant, so looking simply at fuel consumption is insufficient. Instead, Chris uses detailed weather data to calculate fuel consumption per heating degree, allowing him to make a more accurate calculation of energy savings.

There are other variables as well. For example, Chris has to consider factors such as when the building is in use or not. A building in use will see doors opening and letting in cold air and radiant heat from the presence of people. The best time to capture data may be at night when no one is using the facility.

Energy savings may not be obvious, either. If the inserts do decrease air infiltration ("leakiness"), for example, the school's air circulation system may need to kick on more often. The system detects increased levels of CO2 resulting from people exhaling.

Chris thinks some other recommendations could come out of this —for example, reducing the size of the nozzles that regulate the amount of fuel injected into the system. He believes the boilers may be cycling on/off too often, which could be an indication that the system is oversized and operating inefficiently. Smaller nozzles, if the boilers are amenable, could help improve efficiency.

Brent may also have some additional recommendations. For example, the infrared found cold spots in the lower wing between some of the exterior walls and the roof deck, which could be an opportunity for some low-cost caulking or insulation work. There were some cold spots in the ceiling in the upper wing as well. It's difficult to say more without looking above the ceiling tiles, which is beyond the scope of this project.

The inserts are now installed in most windows in the school. However, several operable windows were left untouched in case windows needed to be opened for ventilation.

Other than the inserts' wood frame, they do not dramatically change one's ability to see out the windows, although they do add a small degree of cloudiness (not more than a standard weatherizing plastic you'd get at a hardware store).

The data will take some time to calculate, especially as Chris continues to monitor fuel consumption over the coming weeks. Hopefully, once ready, the data will give EVT a little more of the information it's been looking for, which could lead to increased incentives and interest across the state.

For now, however, the school should at least be a little cozier, especially around the single-pane windows in the lower wing.

Photo credit: Nick Clark (unless otherwise noted). Title photo: Li Shen